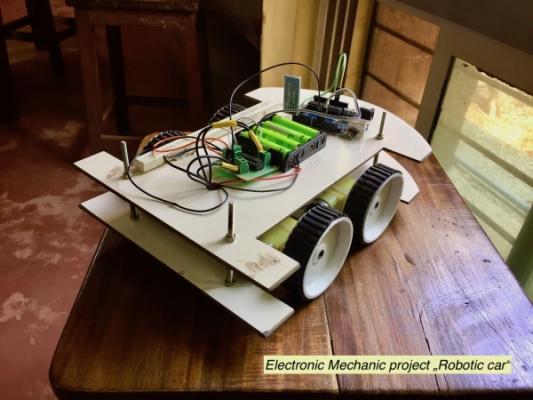

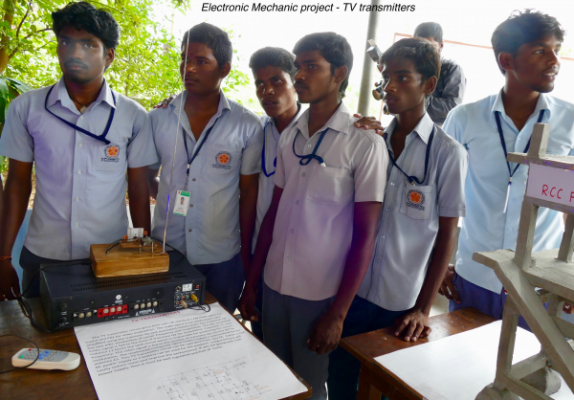

Electronic-Mechanic, regular, first year, project-based learning

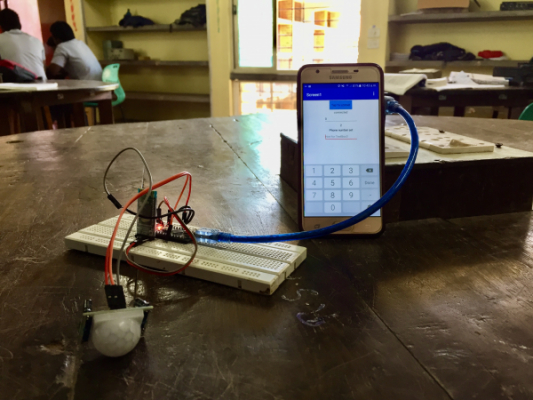

Today the concept of robots is seen as a way to reduce human effort and increase productivity without compromising on quality and accuracy of the work. This project considers the implementation of a robot, which can be operated wirelessly using Bluetooth technology. Integrating hardware and software is the key for this project. By integrating hardware and software, the students found just how much technology can be used to develop an outstanding project. The group went a step further by creating an even safer version of the mower. In addition, the autonomous version is also much more convenient for the user. The project includes a heavy amount of circuitry, programming, and integration of the two. The project was done in two different stages. The first stage the group completed was the android application for the wireless control of the lawn mower. The second stage of their project was creating an Autonomous Lawn Mower. This report describes different aspects (technical and non-technical) of the lawnmower.